Understanding the Numerous Kinds of Welding Techniques and Services Offered

Introduction of Welding Strategies

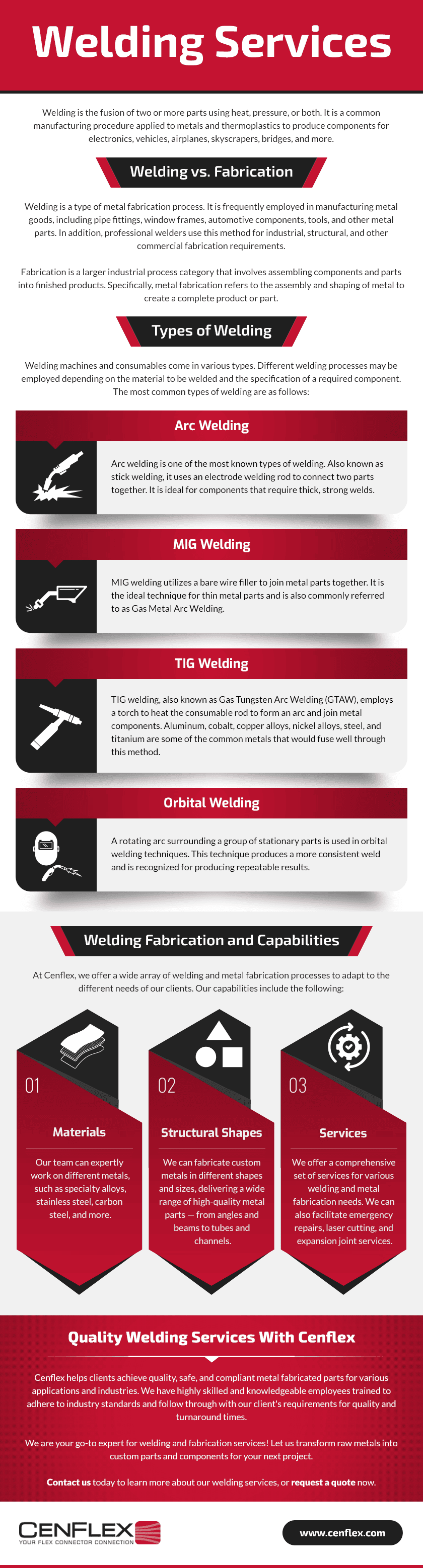

Welding strategies include a varied series of techniques utilized to sign up with materials with each other permanently. One common technique is arc welding, which includes producing an electrical arc in between the base and an electrode product to thaw and fuse them together. This technique is functional and can be made use of with various steels, making it one of one of the most extensively utilized welding processes.

Furthermore, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a tidy and accurate welding approach that utilizes a non-consumable tungsten electrode to develop the weld. TIG welding is typically made use of for thinner materials and gives superb control over the welding procedure. Generally, understanding these different welding methods is important for choosing one of the most appropriate approach for various projects.

Frequently Used Welding Methods

A variety of commonly used techniques are employed in the field of welding to efficiently sign up with products together. Among one of the most commonly made use of strategies is Gas Metal Arc Welding (GMAW), likewise referred to as MIG welding. This approach utilizes a wire electrode that is fed via a welding weapon, in addition to a protecting gas to secure the weld from impurities airborne. An additional usual technique is Protected Steel Arc Welding (SMAW), or stick welding, which makes use of a flux-coated electrode to produce the weld. Tungsten Inert Gas (TIG) welding is preferred for its accuracy and convenience, using a non-consumable tungsten electrode to produce the weld. Flux-Cored Arc Welding (FCAW) is generally used in industrial settings due to its high welding rate and mobility. In Addition, Submerged Arc Welding (SAW) is perfect for producing deep welds on thick materials. These generally utilized welding methods satisfy various requirements and products, supplying options for numerous welding applications.

Advanced Welding Solutions

Structure upon the foundation of typically utilized welding techniques, the world of innovative welding services encompasses advanced strategies and innovations that press the limits of precision and efficiency in product joining procedures. Advanced welding services often include specialized approaches such as laser welding, electron light beam welding, and friction mix welding. Rubbing mix welding, a solid-state signing up with process, allows the welding of products that are challenging to fuse making use of conventional techniques, like light weight aluminum and copper.

Specialized Welding Strategies

Another specialized welding technique is laser beam of light welding, where an extremely focused beam of light of light is utilized to sign up with metals with minimal heat-affected zones and distortion. These specialized welding strategies showcase the diversity and development existing in the area of welding, supplying services for official source a large array of commercial applications.

Picking the Right Welding Refine

Selecting the suitable welding procedure is vital in accomplishing ideal cause steel fabrication and joining operations. With numerous welding methods available, it is crucial to take into consideration variables such as the kind of metal, thickness, joint layout, and preferred end result when selecting the ideal welding procedure - Welding Inspection Service. Among the typical welding methods are Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) GMAW, likewise known as MIG welding, appropriates for welding thin to thick metals and is versatile in different placements. On the various other hand, SMAW, or stick welding, is a trusted technique for outside and field welding as a result of its transportability and simplicity. GTAW, or TIG welding, is excellent for welding slim products and offers precise and high-grade welds. FCAW is favored for welding thick materials and is known for its high welding speeds. Comprehending the qualities of each welding process is important in choosing one of the most appropriate strategy for a specific welding task.

Final Thought

To conclude, recognizing the various types of welding strategies and solutions readily available is vital for picking the right approach for a certain task. By understanding the generally made use of welding techniques, progressed welding solutions, and specialized strategies, people can make enlightened choices to ensure the success of their welding tasks. It is important to take into consideration elements such as materials, project demands, and budget plan when click for source selecting one of the most appropriate welding process.

From standard techniques like stick welding to innovative procedures such as laser welding, the globe of welding uses a multitude of choices for joining metals with each other.In addition, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a tidy and exact welding method that uses a non-consumable tungsten electrode to develop the weld. Advanced welding solutions commonly involve specialized approaches such as laser welding, electron beam welding, and rubbing stir welding. Among the common welding approaches are Gas Metal Arc Welding (GMAW), Shielded Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) By being aware of the commonly made use of welding techniques, advanced welding services, and specialized strategies, individuals can make informed decisions to make certain the success of their welding projects.